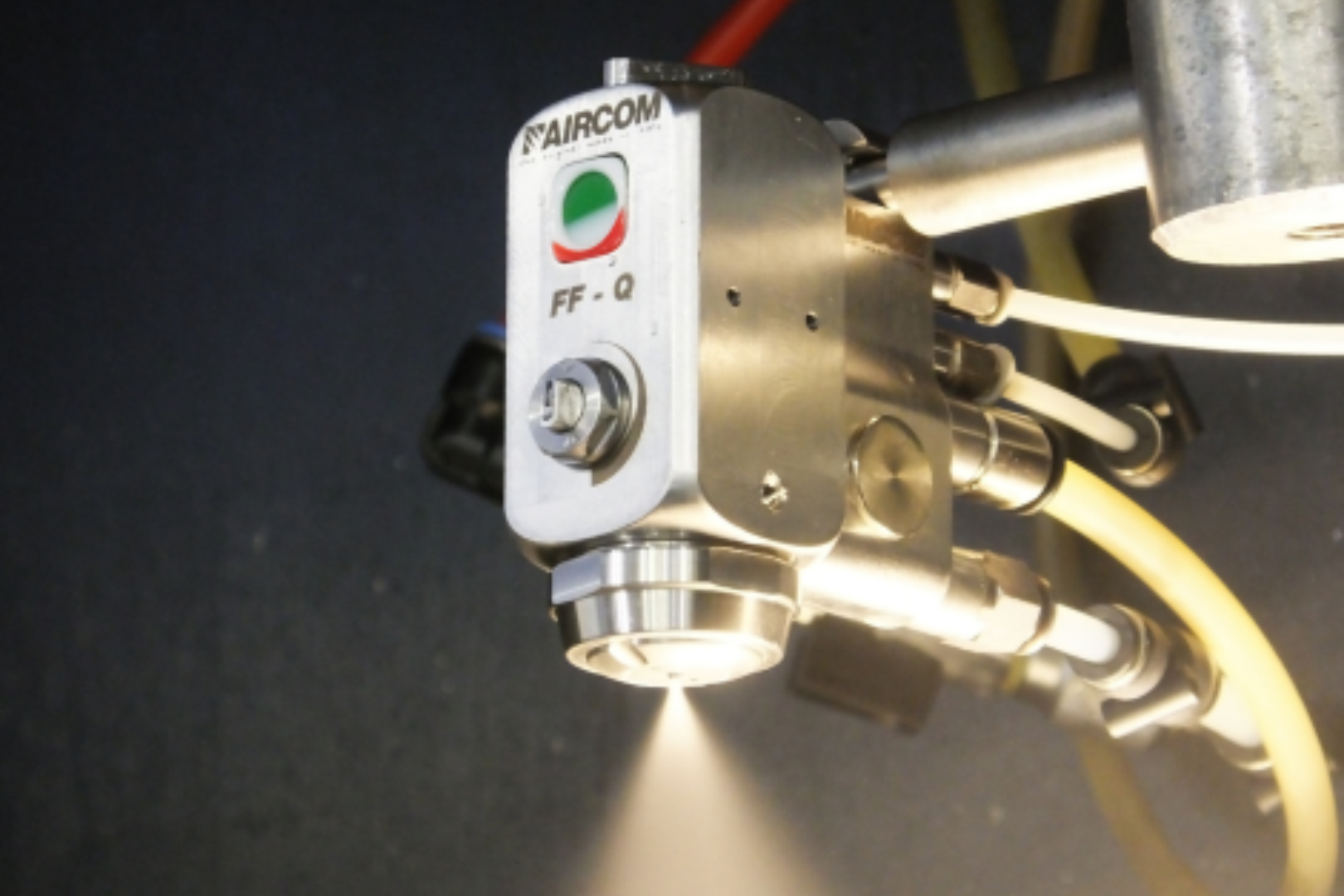

The production focuses mainly on automatic spray guns and their accessories.

Today, with over 50 years of experience, the company can also offer its know-how to a wider audience, guaranteeing 100% Made in Italy products, with the quality and precision that have always distinguished it.

We build tools that allow companies around the world to atomize liquids in an excellent way.

We are committed to designing increasingly innovative products that can meet the needs of our customers, keeping them simple in their use and maintenance.

Discover our production capacity.

We are committed to offering solutions that make processes simpler and more efficient, maintaining the utmost attention to quality. Our products not only guarantee high performance, but also respect the environment thanks to 100% Made in Italy recyclable materials and certifications according to the UNI EN 13966-1 regulation in the IPA Fraunhofer laboratories. The excellence of our products is also reflected in their ease of use: each product is designed to allow simple and autonomous maintenance, supported by explanatory tutorials for correct use and ordinary maintenance, thus ensuring efficiency and practicality for users.

We respond quickly to customer requests, offering customized solutions for different sectors and methods of use. Thanks to our internal design office, we are able to develop new customized products, constantly adapting to customer needs and market evolution. This flexibility allows us to successfully face every challenge, ensuring timely responses and products that perfectly reflect specific needs.

We collaborate with foreign organizations to promote the innovation and evolution of our products, exporting our products all over the world. We also work with highly professional suppliers, carefully selecting the ideal partners for the development of cutting-edge solutions, thus ensuring quality and reliability.

Our products guarantee savings in time and money thanks to their precision and durability, reducing machine downtime. At the same time, we are committed to creating an ergonomic and natural working environment, in line with the principles of Adriano Olivetti, where employee well-being is a priority.

The company was born as a result of the intuition of a young entrepreneur. It was set under the name AIRCOM® DA.

The company is sold to a group of partners already operating in the mechanical and tanning sectors.

New models of automatic spray guns now appear with the historical DA

The company moves to new premises to meet increased production requirements. Everything is designed with a focus on the working quality of the employees.

The AIRCOM® catalog begins to expand and now also offers accessories for spray guns, such as the QRB, quick release block.

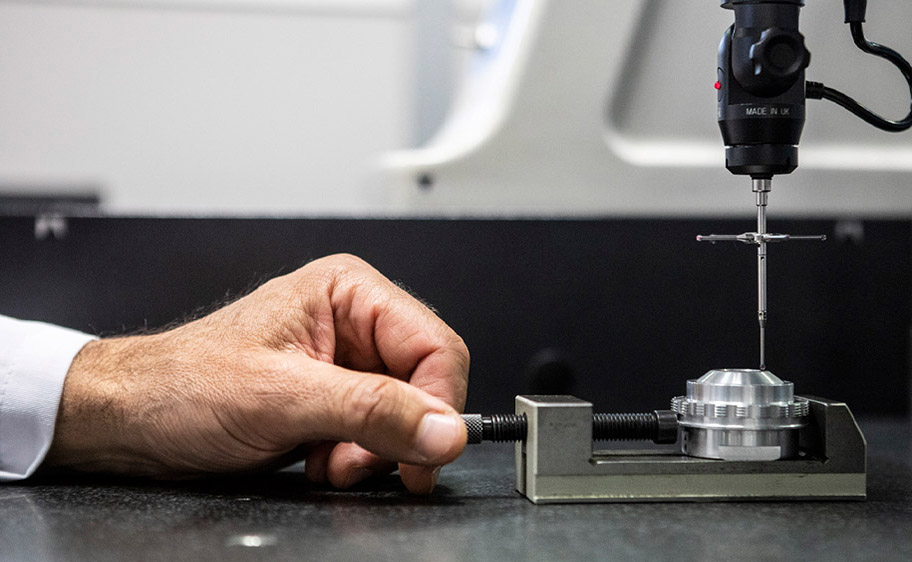

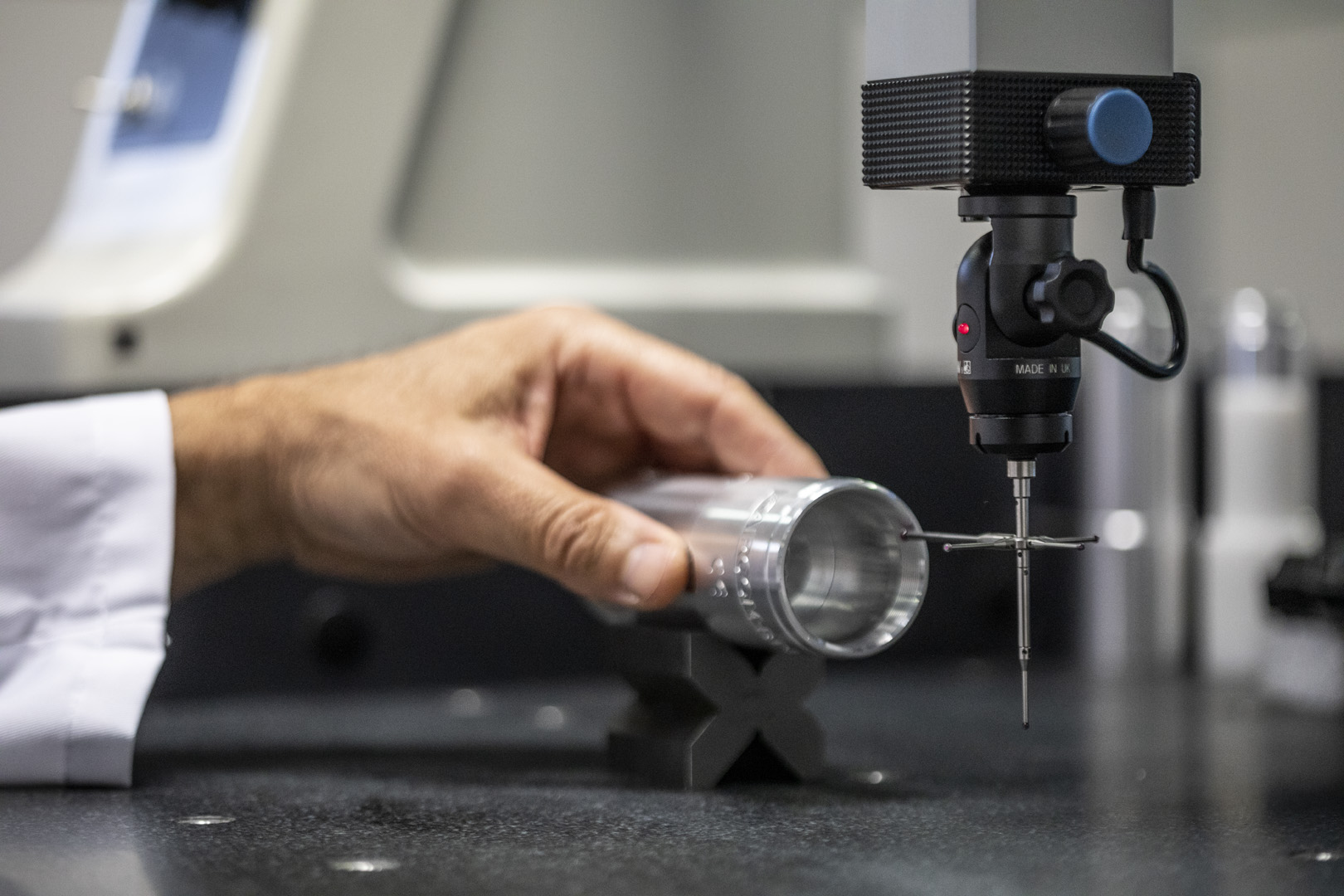

AIRCOM® continues the investment in the quality control of its products, with the improvement of the metrology laboratory and the purchase of state-of-the-art control equipment.

AIRCOM® invests in the design of new products: with the new 3D printer, it is possible to prototype new products, created to meet customer needs.

The company is expanding its product offering, its capacity, and its production plant, with a perspective of future expansion.

A new model of spray gun, designed specifically for the Pharma & Food sector.

We rely on the innovative minds of those who design new products and the expert hands of those who produce and assemble them, guaranteeing careful control over every particular product in our headquarters.

We invest in the continuous training of our people, with advanced technical courses and training experiences to improve teamwork.

Discover our team: find out who is committed every day to create quality products, with attention to detail and precision.